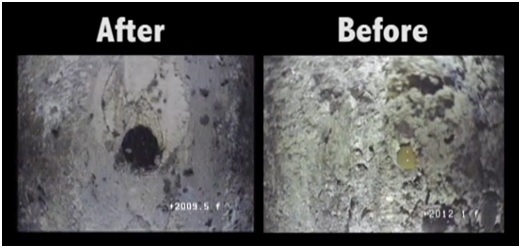

With a spiral, 360 degree brush configuration, the Hyper Scratcher provides double coverage on all inner surfaces of the liner or casing. The nozzle alignment jets a continuous washing of slots or perforations. The filtering system consists of a four foot pup joint, a 40 micron stainless steel strainer placed 30 feet above the tool, and a 30 micron stainless steel strainer located directly on top of the tool. No special work string is required; your existing tubing will do the job. The Hyper Scratcher tool scratches and hyper washes in one trip, resulting in reduced rig time, and that means more money for your business.

Check out the video below for a demonstration of the Hyper Scratcher’s pressure spray nozzles. The brushes have been removed and the water is being run at 500 PSI.